Shenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province

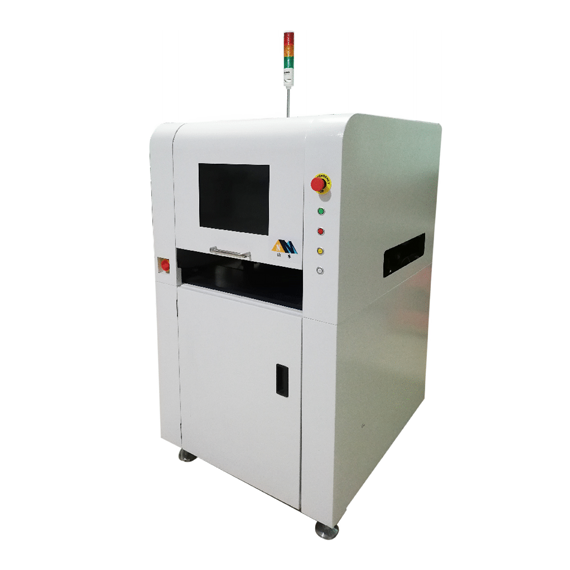

PCB labeling machine is related to the workload of the production line. If the placement machine is not properly maintained, it will have a great impact on it. Today, the placement machine manufacturer will tell you about the placement machine troubleshooting method:

1. PCB labeling machine will cause heat in use. Everyone will worry that this situation will damage the equipment. In fact, the general heating is caused by overloading the equipment. If there is a fever, then everyone should check the internal problems of the equipment and repair it in time.

2. When the PCB labeling machine fails, it is natural to do a good job of repairing. When the placement machine crashes, everyone needs to pay attention to all aspects, and the problem can be solved very well, thus avoiding The huge loss caused by the inability of the equipment to work.

3, in order to ensure that the PCB labeling machine can extend its service life, everyone should carry out good maintenance on the placement machine during normal work, and clean the machine regularly, because some parts of the machine are dirty, it may affect the stickers. The use of the tablet.

4, in some extreme weather, do not use the placement machine, this is indeed the existence of this security risk, it may also have a negative impact on the work, so we need to pay special attention to this point.

So how to quickly find out the cause of PCB labeling machine failure?

The PCB labeling machine is stable. The method I often recommend to my customers is to adjust the device to the set maximum speed, calculate the position of the brake electric eye in the label, and then quickly and continuously trigger the labeling electric eye, remember to observe whether the label is running linearly, stop the trigger and observe The position of the brake electric eye in the label (the position of a good labeling machine should be the same), count the number of labels, the number of the label of a good labeling machine will never be greater than the number of times you trigger, of course, if you are If the label has not been finished yet, the label will be triggered again, and there may be fewer labels.

sound. The characteristics of the PCB labeling machine determine that the marking motor needs to be constantly started and stopped. If you listen to the sound of a company's standard motor starting and stopping the sound, then I tell you that this machine is not tight enough. There is a problem with the selection of the motor.

Exterior. The appearance of the device can reflect the designer's concept of the machine. Of course, the appearance of the author is not general, the appearance refers to the rationality of the device design, such as the difficulty of changing the label, whether the position is adjusted without using tools, and whether the human-machine interface is easy to understand. Good operation, etc. Whether a machine is designed only for the completion of the packaging task, or taking into account the human side, look at the appearance will know. Check that the differential pressure meter has no output. The possible reason is that the sensitivity setting is too high. When the PCB labeler is in operation, each product must be a unique and stable output signal when the fiber is on the bottom of the product. Confirm that the motherboard and the HMI are working properly and the labeling on the HMI is activated.

Tr

Shenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province