Shenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province

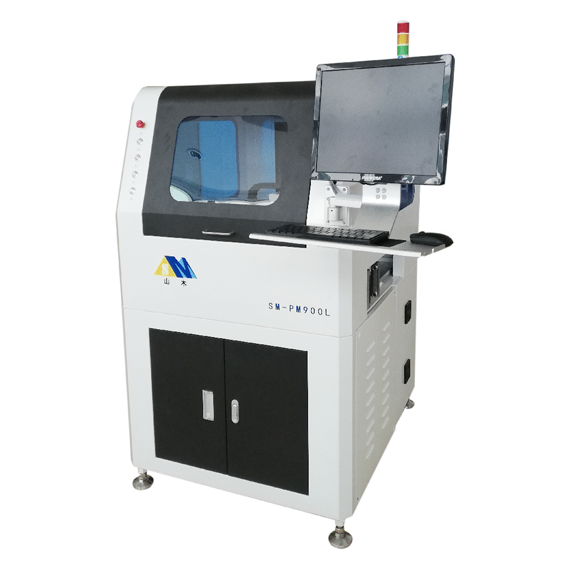

At present, Shanmu Automation's SMT printer has been widely used in the chip manufacturing industry. In the traditional SMT production process, SMT coding and counting are mainly carried out by manual operation. In the manual coding process, the shape and width of the SMT materials involved are different....

Send InquiryShenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province