Shenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province

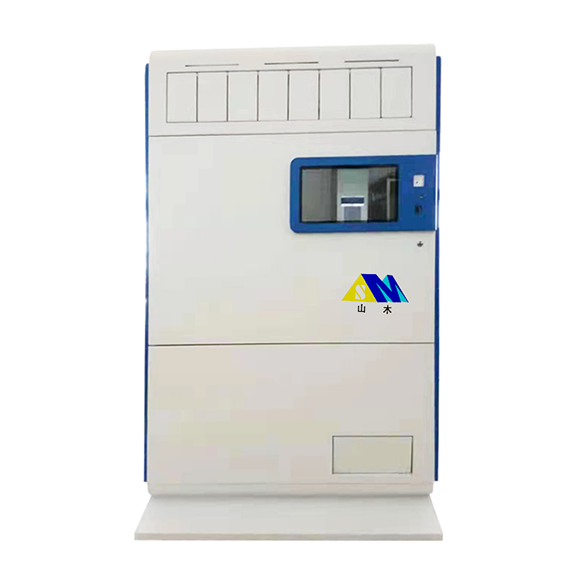

Shanmu automatic solder paste management machine mainly solves the problem: [Study related to tin beads] 1. The solder paste is not fully reheated 2. The solder paste is not fully stirred 2. It has not been reflowed for too long. The solvent evaporates, the paste becomes dry powder, and the ink is dropped....

Send InquiryShenzhen Shanmu Automation Equipment Co., Ltd.

Contact:

13886876029 Cui Manager

Contact number:

0755-29025756

Email:

jack_cui@sunmoonsz.com

address

South China: 3rd Floor, Building 2, Tangzheng Science and Technology Park, No. 152 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

East China: Building 608, Building B, Jiangsu Incubation Park, No. 58 Heshun Road, Suzhou Industrial Park, Jiangsu Province